Predictions of an American manufacturing renaissance in the Midwest—once commonly referred to as the “Factory Belt”—haven’t materialized. Instead, global manufacturers are overwhelmingly migrating to the South, shifting the US economic center of gravity and creating new green jobs… and lots of them.

The Dawning of a New Industrial Age

The Battery Belt didn’t come about by chance—it’s a direct attempt by manufacturers to resolve supply chain vulnerabilities that were exposed in the early days of the COVID-19 pandemic. As the cost of supply chain disruption has continued to climb, manufacturers have taken action to reduce risk by opening facilities closer to the end markets they serve.

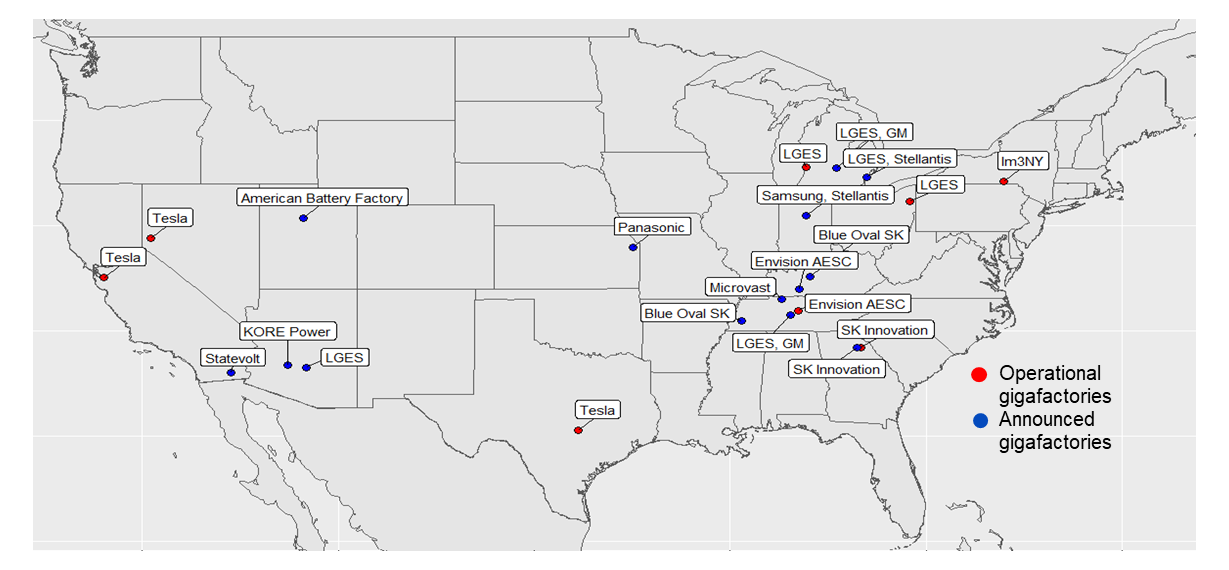

The vast majority of battery capital is currently flowing into just a handful of states, including Georgia, North Carolina, South Carolina, Tennessee, and Kentucky, which begs the question—why these states?

For the most part, it comes down to logistics and where manufacturers can find the best value for their dollar. States in the Battery Belt offer the right interplay of factors for advanced manufacturing, including large, available tracts of land near critical infrastructure like highways, which simplify the transportation of raw and finished goods.

These states also offer high-quality, skilled labor pools at competitive costs. Additionally, the regions are seen as up-and-coming research and development hubs that are conducive to business investment. Manufacturers tend to cluster near existing facilities to take advantage of specialized infrastructure and increased supply chain efficiency, meaning that the Battery Belt is likely to keep expanding—along with the demand for batteries.

What Does the Battery Belt Mean for Cleantech?

The Battery Belt is a critical part of US industrial growth and offers a range of positive spillover effects for battery-dependent industries, most notably electric vehicles (EV) and battery energy storage. This growing network of battery providers reduces the number of imports needed from countries like China, while minimizing supply bottlenecks and delays, ensuring a consistent, profitable, and resilient supply chain.

The Battery Belt will also drive down the cost of domestic battery technology as producers are able to eliminate expensive overseas shipping, all while benefiting from generous domestic subsidies. Passed in August of 2022, the Inflation Reduction Act offers stackable tax credits for every major stage of the battery production process, translating into big affordability gains for cleantech. Battery manufacturers can write off 10% of the cost of active electrode materials while being compensated $35 per kWh of battery cell capacity and $10 per kWh of battery module capacity.

By elevating the EV, energy storage, solar, and other cleantech sectors through reduced battery costs and greater supply chain resiliency, the Battery Belt is becoming a crucial part of the US industrial fabric.

The Next Frontier of the Battery Belt

Several more states are poised to join the Battery Belt, including Florida, Arizona, and most notably, Texas. With similarly favorable manufacturing conditions, these states are attractive locations for growth. Texas, for example, recently beat out a previously announced European site to host the largest battery refinement plant in North America—foreshadowing developments of what’s likely to come.

The establishment and growth of the US Battery Belt is a testament to the South’s economic competitiveness, and will empower the nation’s cleantech sector—from EVs to solar to storage—for decades to come.